20+ Years Experience

Specialist Resin Flooring

Are you looking to have self levelling epoxy flooring installed at your factory or warehouse? Our team offer the very best prices for a self-levelling flooring system.

Self-levelling epoxy flooring is a type of resin flooring that is applied in a liquid form and then self-levels to create a seamless, smooth, and durable surface.

It is typically used for industrial and commercial purposes but has also gained popularity in residential settings due to its many advantages.

If you are interested in costs and installation services, please make sure to get in touch with our team at Epoxy Resin Flooring today using the enquiry form provided.

The average cost of epoxy self-levelling flooring is £85 per square metre in the UK.

However, costs can start at £20 per m² and exceed £150 per m².

It is important to note that the cost can vary depending on a number of different factors.

Some of the factors that can cause costs to vary include:

If you would like a free quotation for epoxy self smoothing flooring, please make sure to complete our contact form today.

Self-levelling epoxy flooring is a type of flooring that is designed to create a smooth and level surface.

It is commonly used in commercial and industrial settings where a seamless and durable floor is required.

The self-levelling property of this flooring system allows it to flow and settle evenly, resulting in a smooth and level finish.

This flooring is typically made up of two main components: epoxy resin and a self-smoothing agent.

It offers several benefits, including easy maintenance, resistance to chemicals and abrasion, and a seamless appearance.

Overall, self-levelling flooring system is a popular choice for achieving a high-quality and durable floor surface.

This type of flooring is created by mixing epoxy resin with a curing agent and can be customised with different colours and patterns.

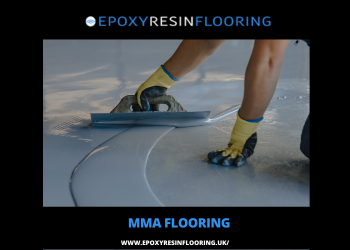

To apply epoxy self-levelling flooring, the surface must be properly cleaned and prepped first. The epoxy mixture is then poured onto the floor and spread evenly with a squeegee or roller.

As the mixture cures, it will level itself out to create a smooth and seamless finish. A second coat may be necessary for added durability and protection.

To apply self-smoothing epoxy flooring, it is important to get a professional to follow these steps:

Self levelling epoxy flooring is a popular choice for both residential and commercial spaces due to its numerous benefits.

Self smoothing resin provides a seamless and smooth surface and high durability. The seamless flooring has both chemical resistance and slip resistance making it an ideal choice for various uses.

In this section, we will explain the various advantages of self smoothing floors in the following section.

Self-levelling epoxy flooring provides a continuous and smooth surface, offering a range of benefits for various applications.

A continuous and smooth surface is desirable for residential, commercial, and industrial spaces due to its clean and professional appearance.

It also offers easy maintenance and durability against wear, chemicals, and stains. However, limited colour options and the need for professional installation should be considered as potential disadvantages.

Epoxy self-levelling flooring offers high durability and resistance, making it an excellent choice for various applications. Here are the steps to achieving its durability and resistance:

By following these steps, you can achieve a self-smoothing epoxy floor coating with exceptional durability and resistance.

Easy maintenance is one of the key advantages of an epoxy self-levelling flooring system. Here are some steps to ensure its cleanliness and longevity:

By following these steps, you can keep your self-smoothing epoxy flooring looking clean and well-maintained.

Self-levelling epoxy flooring offers excellent chemical and stain resistance, making it a popular choice for various applications.

While self-levelling epoxy flooring has many advantages, it is important to also consider its potential drawbacks. In this section, we will discuss the disadvantages of choosing this type of flooring.

From limited colour options to the need for professional installation, there are a few key factors to keep in mind.

Additionally, we will explore how self-levelling epoxy flooring can become slippery when wet, and what precautions can be taken to prevent accidents.

By understanding these potential downsides, you can make an informed decision about whether self-levelling flooring is the right choice for your space.

Limited colour options are one of the drawbacks of self-levelling flooring. Here are steps to overcome this limitation:

Professional installation is essential for successfully applying epoxy self-levelling flooring. Here are the steps involved in the professional installation process:

When considering self-levelling epoxy flooring, it is important to be aware of its potential slipperiness when wet. To reduce this issue, follow these steps to create safer flooring:

By implementing these measures, you can minimise the risk of slipping on self-levelling epoxy flooring, creating a safer environment.

Self-levelling epoxy flooring has gained popularity in a wide range of applications because of its durability, versatility, and visual appeal.

In this section, we will explore the various areas where self-levelling flooring can be utilised.

From residential properties to commercial and industrial spaces, including garages and workshops, we will delve into the extensive range of uses that this type of flooring offers.

So, let’s delve into the different applications of epoxy self-levelling flooring and the benefits it provides to various types of spaces.

Self-levelling epoxy flooring is a popular choice for residential buildings due to its many advantages.

Here are the steps to install and maintain self-levelling epoxy flooring in residential buildings:

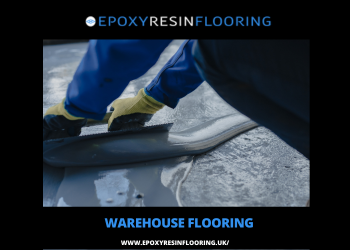

Commercial and industrial spaces can greatly benefit from self-levelling epoxy flooring.

Warehouses, factories and food preparation areas are all common spaces for epoxy resin to be installed. Due to the properties of the hygienic surface, it is perfect for hospitals and food preparation areas such as commercial kitchens.

Here are the steps to apply this type of flooring in such areas:

Garages and workshops greatly benefit from the installation of self-levelling flooring. Here is a list of steps to consider for garages and workshops:

Maintaining self-levelling epoxy flooring is important for preserving its durability and appearance. In this section, we will discuss the best practices for keeping your epoxy flooring in top condition.

From regular cleaning and sweeping to avoiding harsh chemicals, we will cover the necessary steps for maintaining your flooring.

Additionally, we will explore the importance of addressing any damages promptly to prevent further issues. Follow these tips to ensure your epoxy self-levelling flooring stays looking its best for years to come.

Regular cleaning and sweeping is essential for maintaining the longevity and appearance of epoxy self-levelling flooring. Here are the steps to keep your floor in top condition:

To avoid damaging self-levelling epoxy flooring, it is important to take precautions when cleaning and maintaining the surface. Here are some steps to avoid harsh chemicals:

By following these steps and using gentle cleaning methods, you can maintain the integrity and appearance of your self-levelling flooring.

Addressing any damages promptly is essential for maintaining the longevity and appearance of self-levelling epoxy flooring. Here are steps to follow:

By addressing damages promptly, you can preserve the integrity and appearance of your epoxy self-levelling flooring for years to come.

Are you thinking about installing self-leveling epoxy flooring in your home or business?

Before you begin the process, it is important to understand the initial steps involved.

In this section, we will go over the first steps of working with our expert epoxy flooring installers.

From the initial consultation to the customised solutions provided, we will assist you in achieving a smooth and long-lasting epoxy flooring finish.

An initial consultation is an important step in the process of installing self-levelling epoxy resin floors.

During this consultation, the flooring experts will assess your needs and provide personalised solutions. Here is a step-by-step guide to the initial consultation:

When it comes to self-levelling epoxy flooring, tailored solutions are crucial for achieving the desired outcome.

These customised solutions take into account the specific needs and requirements of each project, ensuring optimal results.

Tailored solutions involve a thorough assessment of the space, considering factors like floor condition, purpose, and desired aesthetics.

By tailoring the installation process and materials used, professionals can address any unique challenges and deliver a seamless and durable flooring solution.

Whether it’s a residential building, commercial space, or garage, tailored solutions ensure that the epoxy self-levelling flooring meets the specific needs of the client.

Self-levelling epoxy flooring is a popular choice for commercial and industrial spaces because of its durability and ease of maintenance.

It provides a smooth and seamless surface that is resistant to chemicals, stains, and scratches. This type of flooring is applied in liquid form, allowing it to level itself and create a consistent finish.

It is commonly used in areas such as industrial warehouses, factories, showrooms, and garages.

Overall, self-levelling epoxy flooring is a practical and long-lasting solution for spaces that require a high-performance floor.

If you would like to find out about the different types of resin flooring we can install for industrial spaces, please get in touch with our team today.

The pot life of epoxy self smoothing is typically between 20-30 minutes, and the full cure time is around 8-12 hours.

However, this may vary depending on the surrounding air temperatures and level of ventilation.

4.5 litres of Professional SLC 2000 Industrial can cover approximately 10 square metres at a thickness of 1mm.

Epoxy self levelling is specifically formulated for application on damp floors.

However, the substrate should be prepared properly and any heavy oil residue or grease should be brushed off before application.

Resincoat epoflow self levelling screed has a high strength and wear resistance, making it suitable for heavy duty traffic and industrial situations.

It also cures quickly, allowing for early return to use. Additionally, it is available in multiple colours and can be pump applied for larger areas.

Self levelling epoxy flooring is only suitable for use on non-porous surfaces such as existing painted floors, cement screeds, and new concrete floors that have been sufficiently sealed.

It is not recommended for use on weaker floors or surfaces with heavy oil contamination. A primer may be needed for certain substrates.

There are a range of other services that we can provide. Have a look at the list below for more information:

We Aim To Reply To All Enquiries With-in 24-Hours